Sheet metal fabrication

All uploads are secure and confidential

Why choose Metal Market?

- Instant quotes & DFM analysis

- Parts in as fast as 2 days

- Cutting tolerance ±0.2mm

- ISO 9001:2015 certified partners

- Multiple surface finishes available

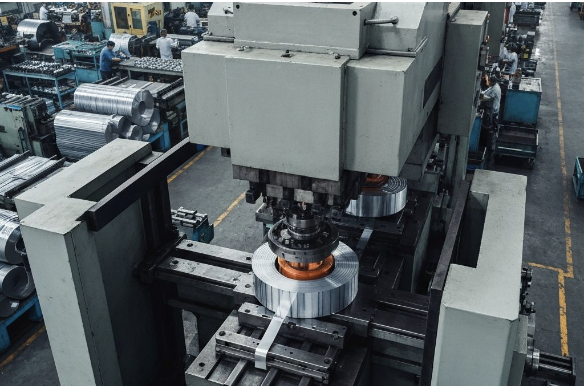

Our sheet metal fabrication capabilities

Our network of manufacturing partners gives you easy access to sheet metal fabrication capabilities to serve all your manufacturing needs.

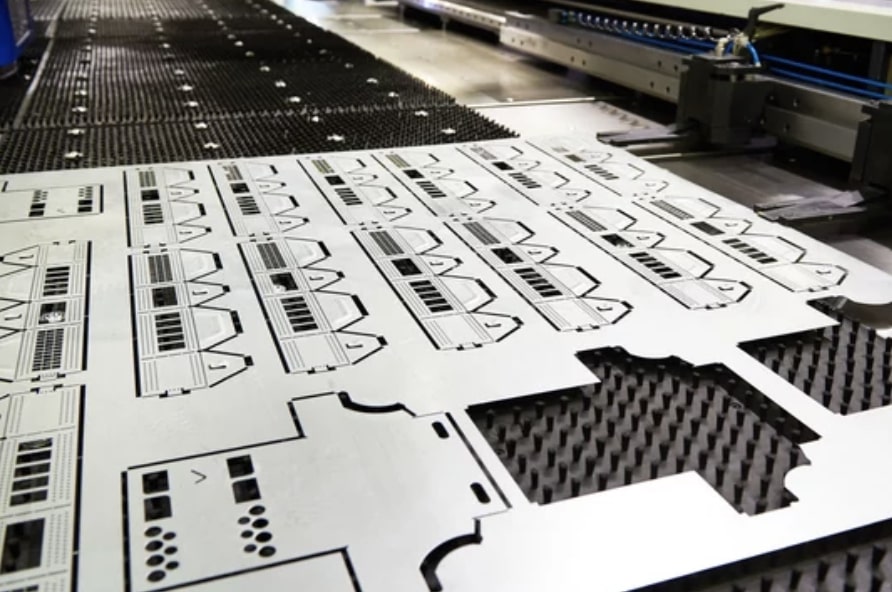

Laser cutting

This manufacturing process uses a high-power laser beam to cut a material sheet with precision and speed.

- Allowable sheet thickness: 1-6mm (depending on material)

Bending

This manufacturing process uses dies to produce U-shape, V-shape or channel shape along a straight axis in ductile materials.

- Allowable sheet thickness: 1-6mm (depending on material)

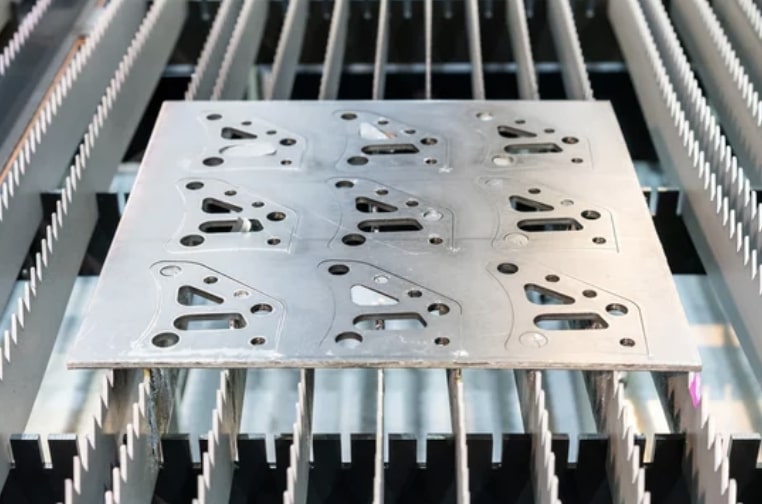

Gallery of sheet metal products

Here's a small selection of the sheet metal parts we've produced for our customers across various industries.

Sheet metal fabrication materials

Here is a list of our standard available metals for sheet metal fabrication.

Available Metals

Aluminum

Excellent strength-to-weight ratio, good corrosion resistance. Ideal for enclosures, brackets, and aerospace components.

Available alloys: 5052, 5754

Learn moreStainless Steel

High corrosion resistance, excellent durability. Perfect for medical, food processing, and outdoor applications.

Available alloys: 304, 316L

Learn moreMild Steel

Cost-effective, easy to weld and form. Suitable for structural components and industrial applications.

Available alloys: 1018

Learn moreWe can source any other material on request. Contact sales@metalmarket.com for custom materials.

Tolerances for sheet metal fabrication

The table below summarizes the standard tolerances of parts produced by our certified manufacturing partners.

| Feature | Tolerance |

|---|---|

| Cutting feature | ± 0.2mm (0.00787") |

| Bend angle | ± 1.0° |

| Bend to edge | ± 0.254mm (0.010") |

Available surface finishes

Surface finishes are applied after fabrication and can change the appearance, surface roughness, hardness and chemical resistance of the produced parts.

Standard

Parts delivered as cut and bent. Sharp edges broken and deburred for safe handling.

Bead blasted

Parts bead blasted with glass beads for a grainy texture finish.

Brushed

Parts manually brushed with grit #180 to reduce surface roughness.

Brushed + Anodized Type II

Manual brushing followed by anodizing for improved corrosion resistance.

Bead blasted + Anodized Type II

Bead blasting followed by anodizing for corrosion resistance.

Anodized Type III (Hardcoat)

Hardcoat anodizing for improved corrosion and wear resistance.

Powder coated

Powder coating layer applied for durable, colored finish.

Black oxide

Black oxide coating for improved corrosion resistance and reduced light reflection.

Chromate conversion

Alodine coating for corrosion resistance while maintaining conductivity. RoHS compliant.

Our ordering process

Upload CAD file

Securely upload your part design to our online quote builder

Confirm specs

Configure your part specifications and select a lead time

Receive quote

Get an instant quote for your parts

Manufacturing

We select the best manufacturer and production begins

Quality control

We ensure parts are manufactured to our standards

Delivery

Your parts are delivered to your door

Frequently asked questions

Our other manufacturing capabilities

CNC machining

Milling (3-, 4- & full 5-axis), turning and post-processing

- 50+ metals and plastics & 10 surface finishes

- Tolerances down to ±0.0008" (0.020 mm)

- Lead times from 5 business days

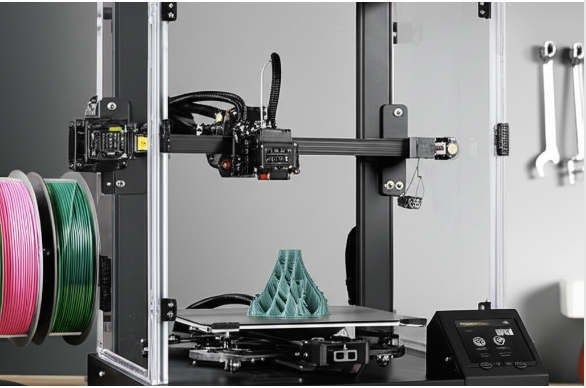

3D printing

FDM, SLS, MJF, SLA

- Dimensional accuracy from 0.2%

- 25+ plastics & 35+ colors

- Lead times from 1 business day

Injection molding

Prototypes and production tooling

- Wide range of part complexities and sizes

- 1 to 1M+ parts production capacity

- Lead times from 10 business days

Compression molding

Rubber and composite parts

- 9 certified materials including silicone & EPDM

- Tolerances as low as +/- 0.02"

- Lead times from 10 business days

Die casting

High & low pressure casting

- Certified aluminum, zinc & magnesium alloys

- Tolerances as low as +/- 0.003"

- Samples as fast as 10-15 days

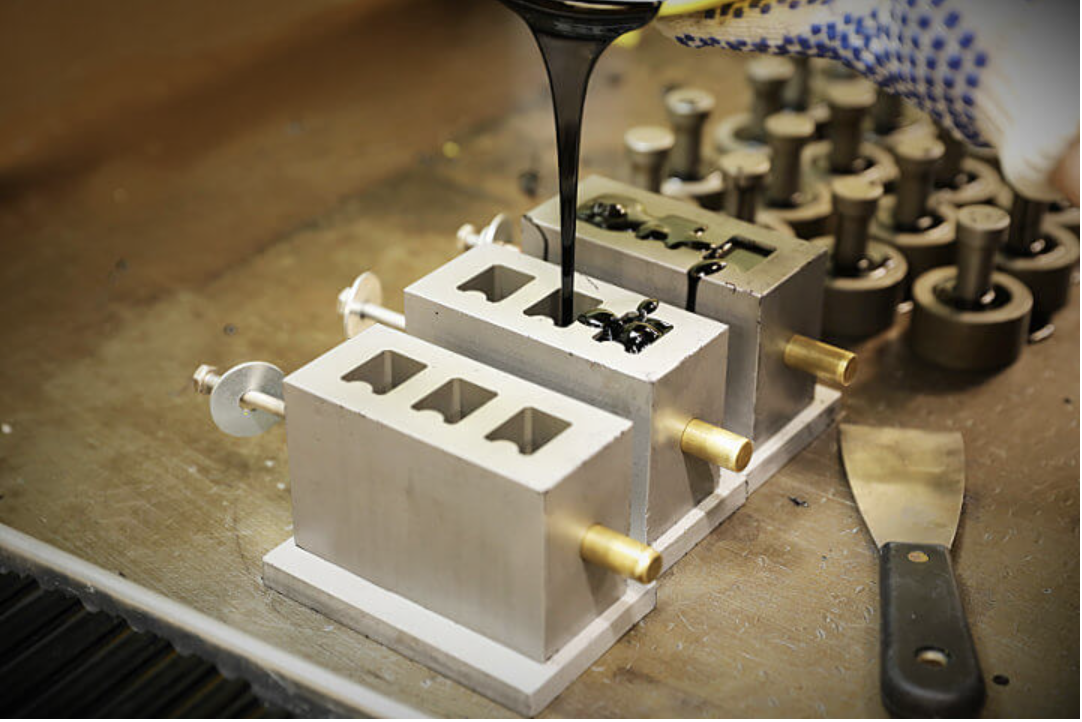

Urethane casting

Production quality at low volumes

- ABS-like, Nylon-like, elastomer materials

- Parts as fast as 10 days

- 10-200 units per project

Metal stamping

Progressive die, deep draw, fourslide

- Steel, stainless steel, copper & brass

- Tolerances as low as +/- 0.003"

- Production volumes up to 1M+ parts