Injection Molding Service

All uploads are secure and confidential

Why choose Metal Market?

- Instant quotes & DFM analysis

- Lead times from 10 days

- Tool shot life up to 1M units

- ISO 9001:2015 certified partners

Our custom injection molding services

Create parts of all complexities sized from 3 mm to 2 m with Metal Market. Lead times are as fast as 10 days.

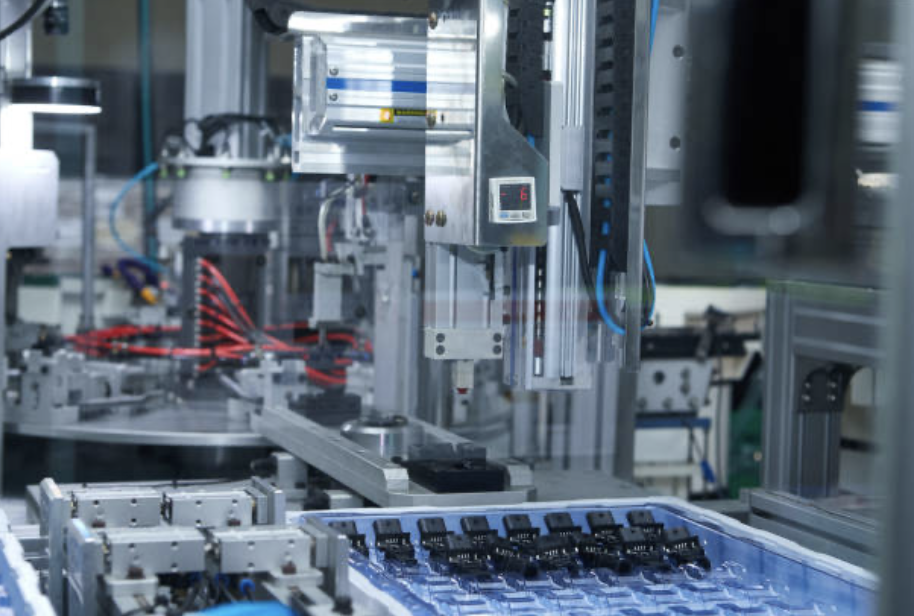

Plastic injection molding

Injection molding is the manufacturing process of injecting high-pressure thermoplastic into a mold. Ideal for high-volume production with consistent quality.

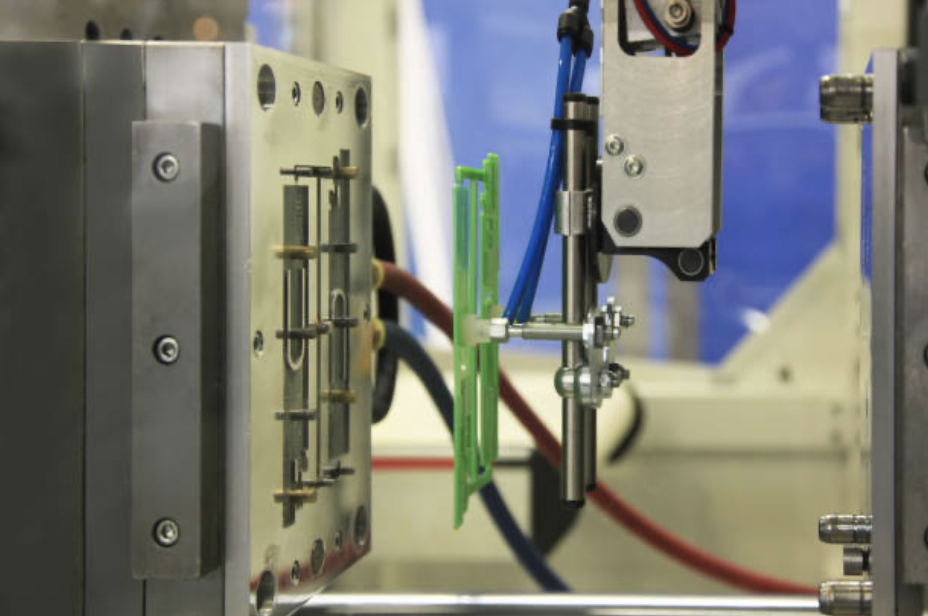

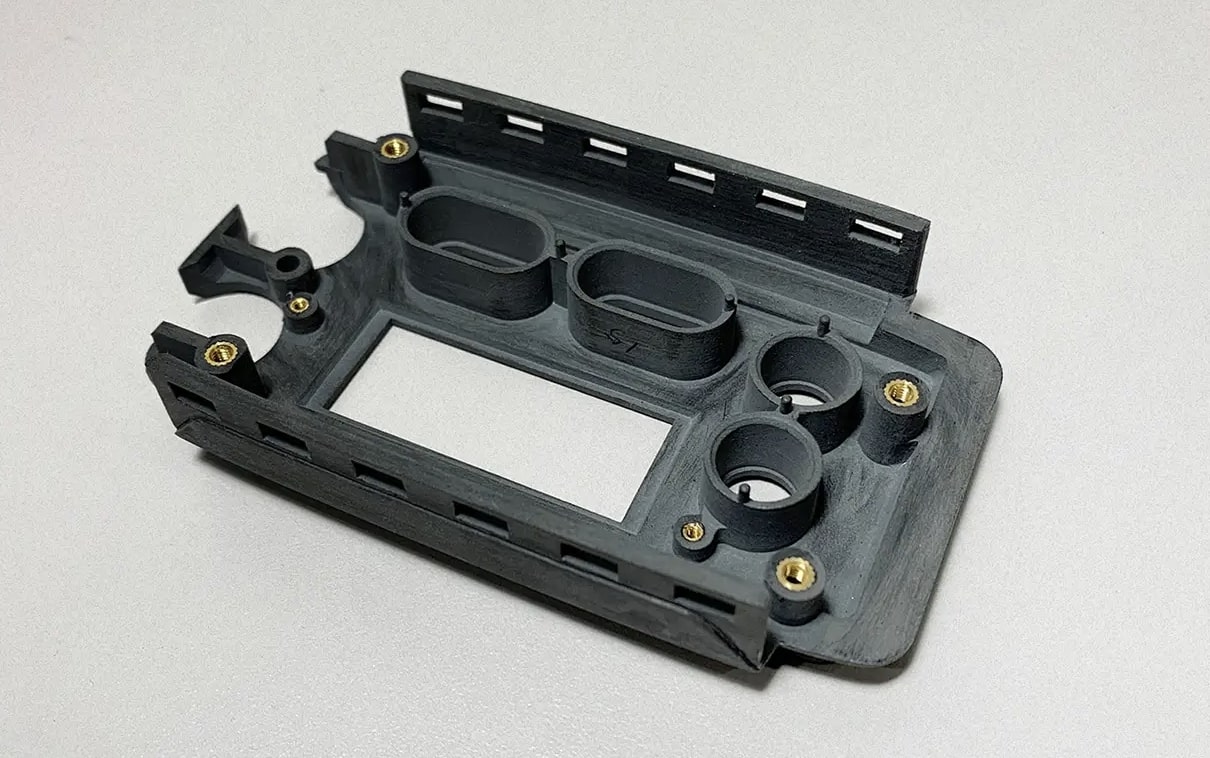

Insert molding

A manufacturing process in which a part is molded around a pre-installed insert in the tooling for enhanced functionality.

Overmolding

A manufacturing process in which one plastic material is molded over another to create a single component with multiple properties.

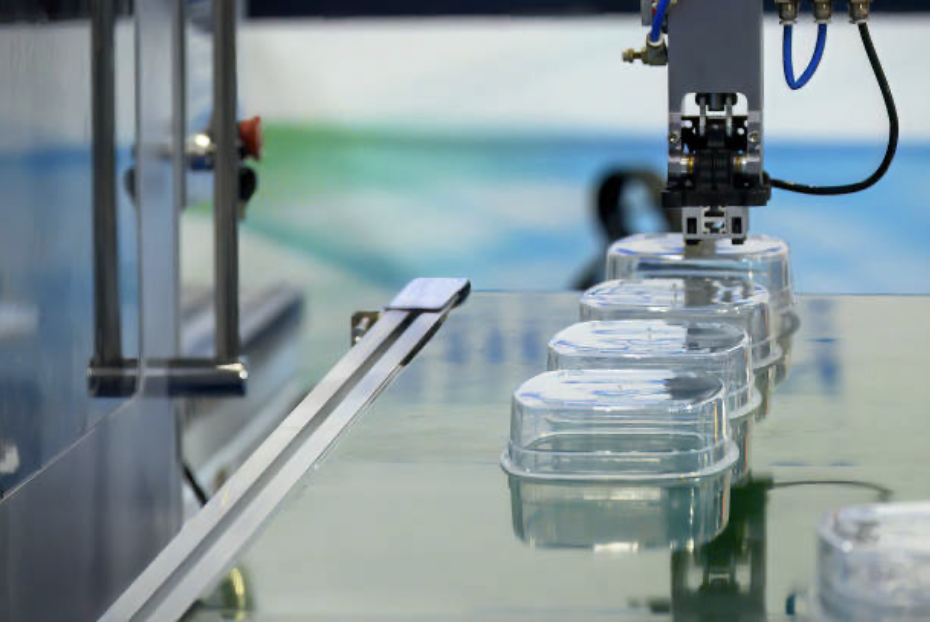

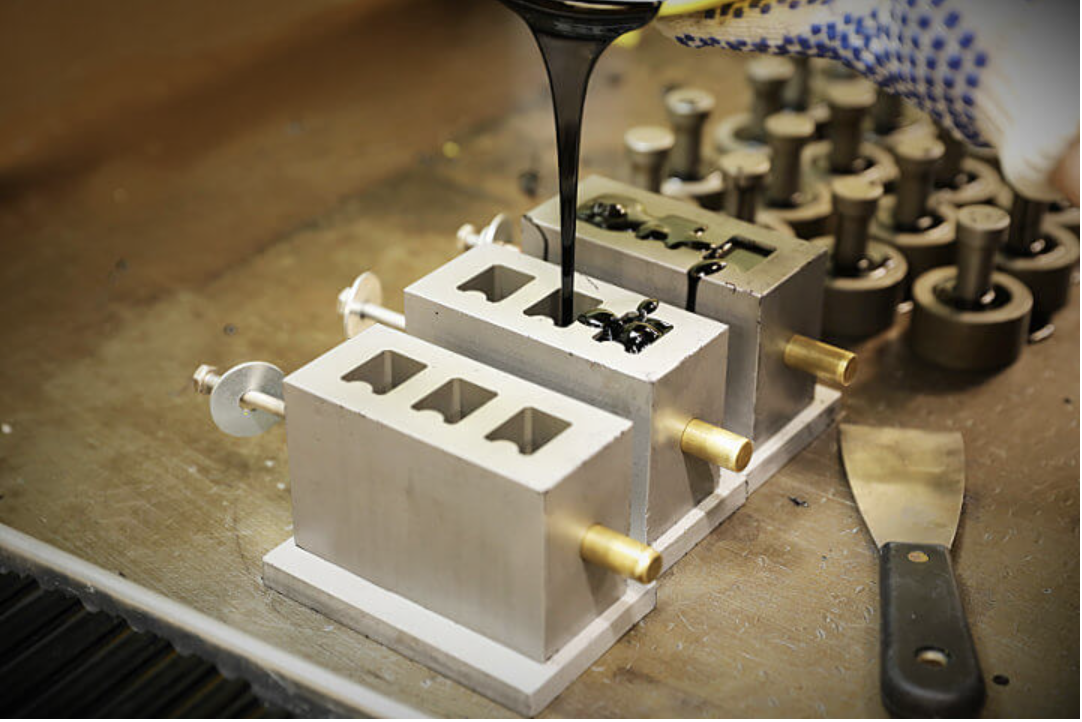

Liquid silicone rubber molding

A thermoset process that involves mixing a two-part solution together to produce flexible and durable parts.

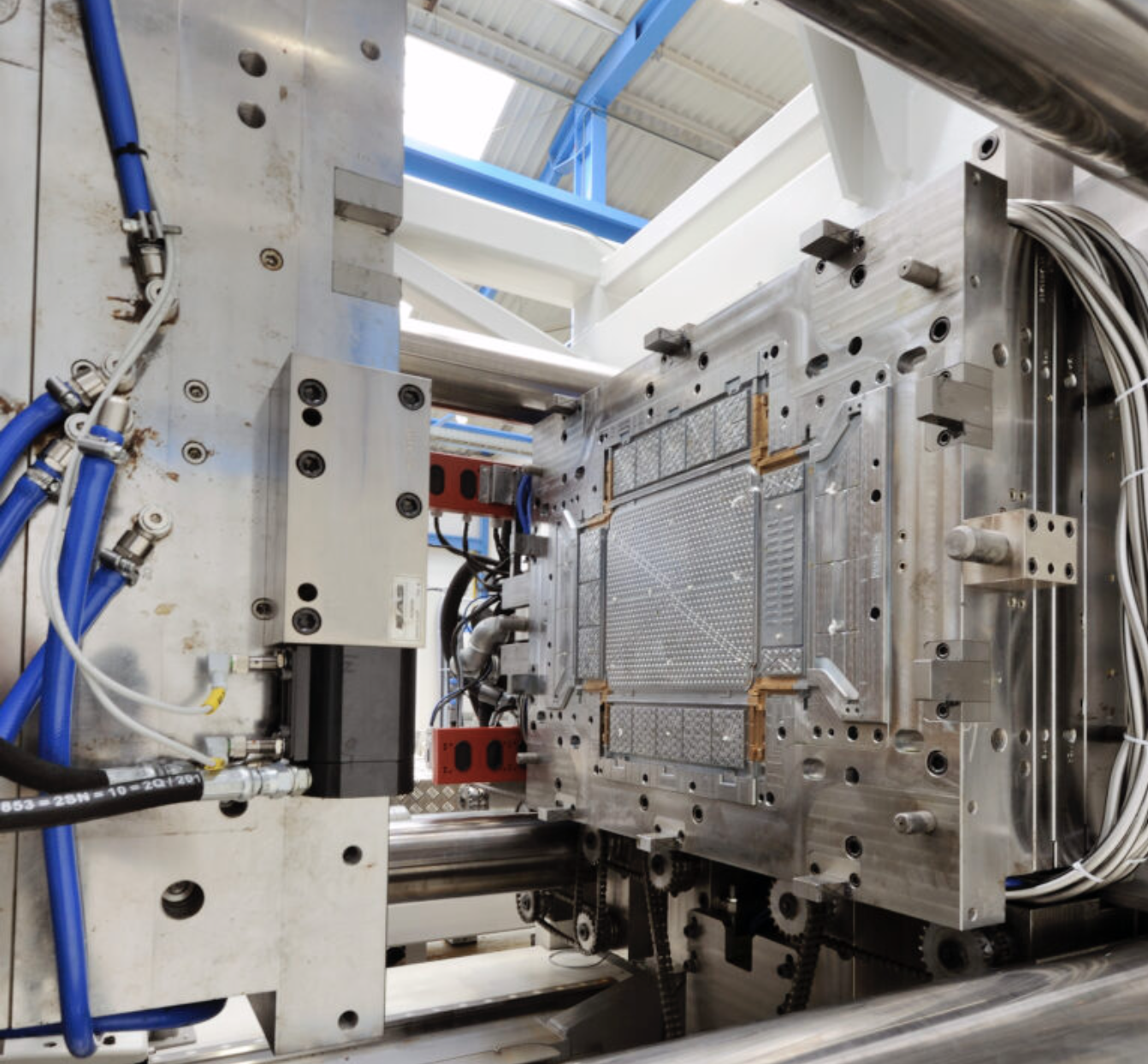

Tooling options

Choose between prototyping and production tooling based on your volume requirements.

Prototyping

- Ideal for rapid prototyping and low-volume production

- Tool shot life – 1k to 100k units

- Fast turnaround and cost-efficient construction

- Aluminum or steel tooling

Production

- Longer-lasting tooling for larger volumes

- Tool shot life – 100k to 1M units

- Automated production for cost-efficiency at higher volumes

- Hardened steel for longer life and scalable unit price

Gallery of injection molded parts

Here's a small selection of the injection molded prototypes and end-use parts we've produced for our customers.

Injection molding materials

We can generate instant injection molding quotes for 15+ thermoplastics and thermosets.

Thermoplastics

ABS

Acrylonitrile Butadiene Styrene offers excellent impact resistance, good mechanical properties, and is easy to process. Ideal for consumer products and housings.

Polycarbonate

High impact strength, optical clarity, and heat resistance. Perfect for transparent parts, safety equipment, and electronic housings.

Nylon (PA)

Excellent wear resistance, low friction, and good chemical resistance. Commonly used for gears, bearings, and structural components.

Specialty Materials

We can source any other material on request, but quotes take up to 48 hours.

Secondary operations

We offer several secondary operations such as painting or heat tapping inserts. You can specify which secondary operations are needed in your quote request.

Our ordering process

Get your injection molded parts in 6 simple steps.

Upload CAD file

Securely upload your part design to our online quote builder

Confirm specs

Configure your part specifications and select a lead time

Receive quote

Get an instant quote for your parts

Manufacturing

We select the best manufacturer and production begins

Quality control

We ensure parts are manufactured to our standards

Delivery

Your parts are delivered to your door

Frequently asked questions

Our other manufacturing capabilities

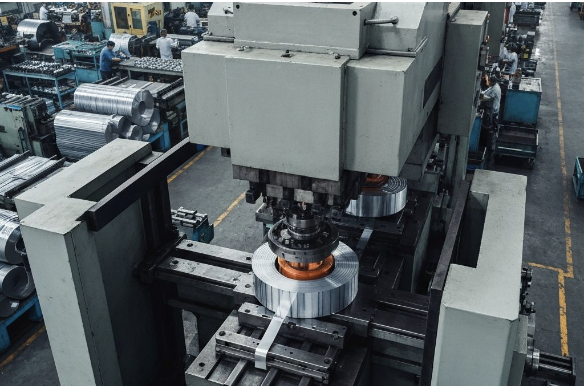

CNC machining

Milling (3-, 4- & full 5-axis), turning and post-processing

- 50+ metals and plastics & 10 surface finishes

- Tolerances down to ±0.0008" (0.020 mm)

- Lead times from 5 business days

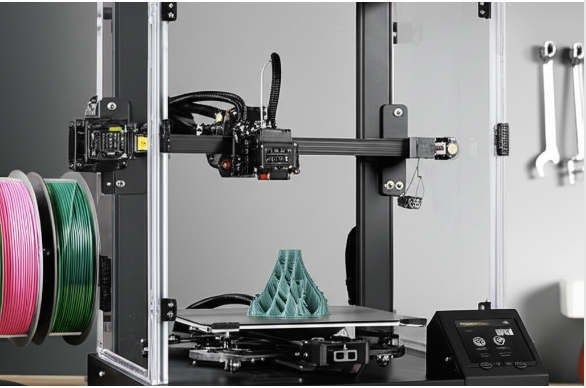

3D printing

FDM, SLS, MJF, SLA

- Dimensional accuracy from 0.2%

- 25+ plastics & 35+ colors

- Lead times from 1 business day

Sheet metal fabrication

Laser cutting, bending, post-processing

- 6 metals & 9 surface finishes

- Tolerances down to ±0.004" (0.010 mm)

- Lead times from 5 business days

Compression molding

Rubber and composite parts

- 9 certified materials including silicone & EPDM

- Tolerances as low as +/- 0.02"

- Lead times from 10 business days

Die casting

High & low pressure casting

- Certified aluminum, zinc & magnesium alloys

- Tolerances as low as +/- 0.003"

- Samples as fast as 10-15 days

Urethane casting

Production quality at low volumes

- ABS-like, Nylon-like, elastomer materials

- Parts as fast as 10 days

- 10-200 units per project

Metal stamping

Progressive die, deep draw, fourslide

- Steel, stainless steel, copper & brass

- Tolerances as low as +/- 0.003"

- Production volumes up to 1M+ parts