Source custom parts for the robotics industry

- Custom parts with varying levels of complexity

- Ideal for prototyping or full production runs

- Fast and reliable with local and global manufacturing options

All uploads are secure and confidential

Manufacture robotics with digital efficiency

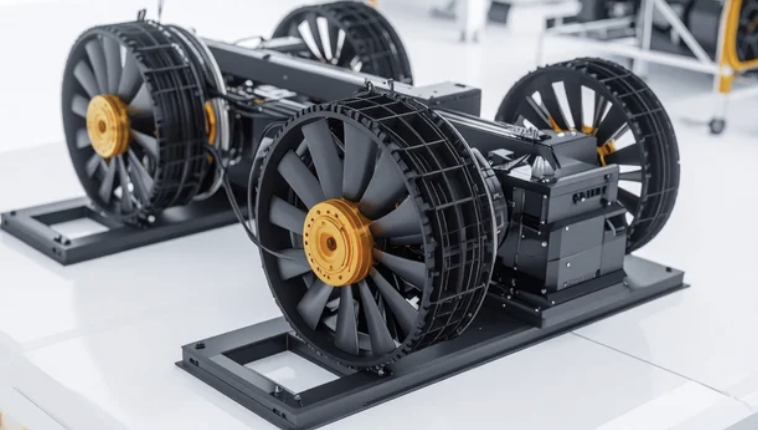

With a huge variety of manufacturing capabilities available for low-volume prototyping through to full-scale production, Metal Market provides everything you need to build robotics. Whether you're developing unique end effectors, customized fixtures or workholdings, or an entirely new robotic system with a large number of custom components, our network of trusted manufacturers provides limitless capacity for making highly customized parts.

Certified for every application

Metal Market is ISO 9001 certified and our suppliers have industrial certifications.

- ISO 9001

- ISO 14001

- AS 9100

- PPAP

Comprehensive quality documentation

Get validation reports to ensure the highest quality and compliance.

- CMM Inspection Report

- Full Dimensional Inspections

- Material Test Reports

- Certificates of Conformance

Highest quality standards

We use a rigorous set of protocols and procedures to maintain quality.

- Special tooling

- Dimensional checks

- Review of all documentation

- Full IP protections

Parts in 2 days with Metal Market

Metal Market and its network work together to bring you the world's most comprehensive manufacturing solution. While the network can provide a large breadth of capabilities, our factories offer expedited manufacturing with automated in-house machines for the industry's fastest lead times.

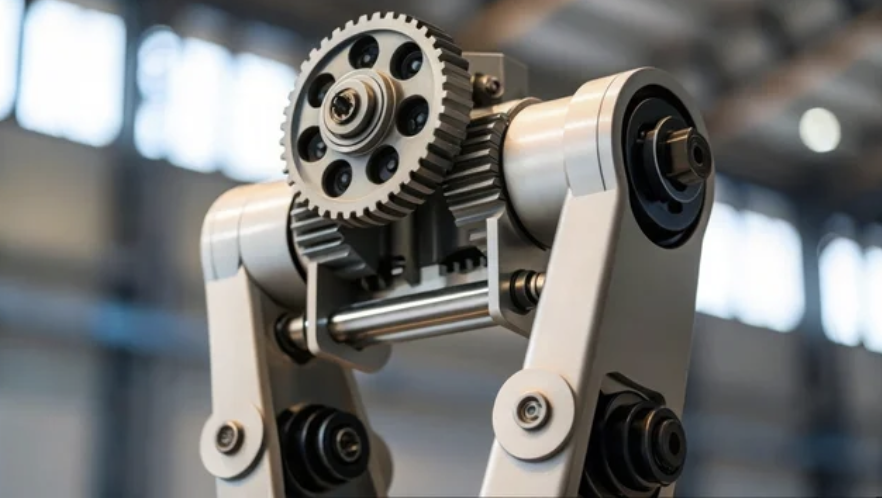

How robotics & automation engineers use Metal Market

Robotics & automation manufacturing capabilities

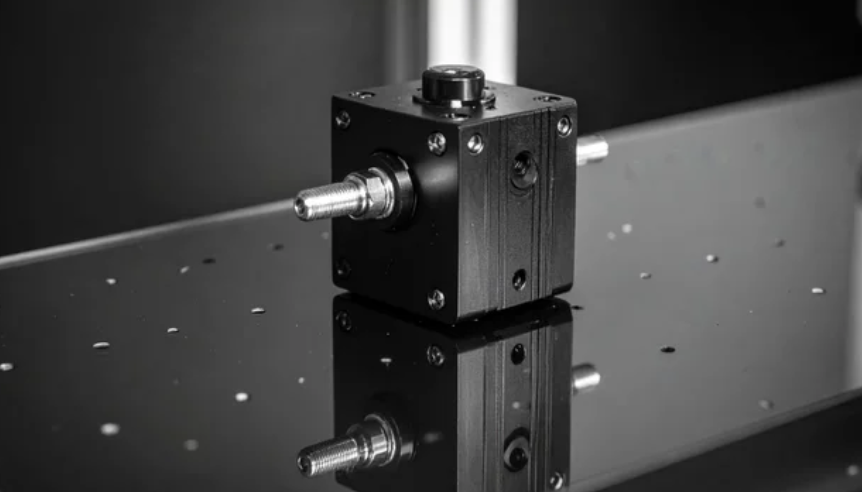

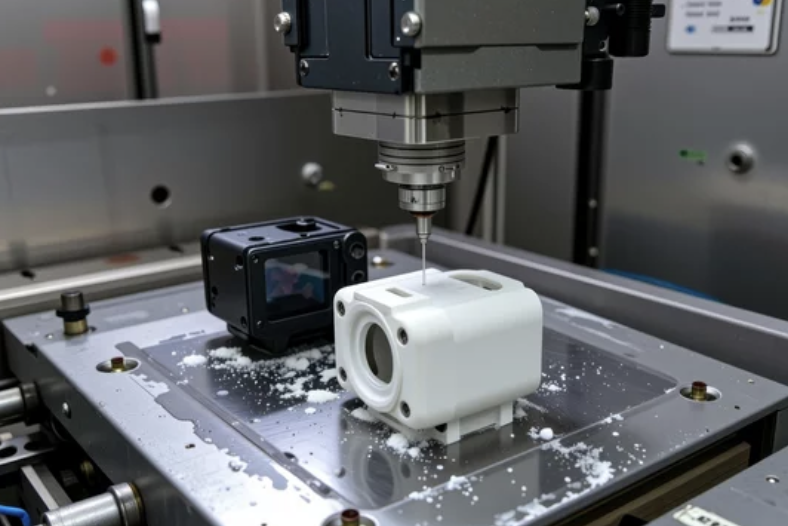

CNC turning

Lathes and live tooling ideal for cylindrical parts

- • 60+ metals & plastics, including 10+ aluminum & 20+ steel

- • Lead times from 5 business days

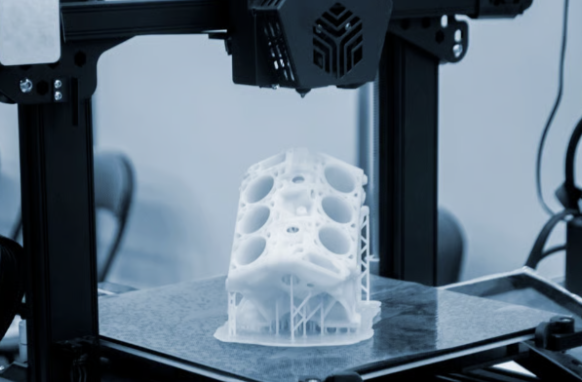

3D printing

FDM, SLA, SLS, MJF

- • 25+ plastics & 35+ colors

- • Lead times from 1 business day

Sheet metal fabrication

Laser cutting, bending, and post-processing

- • Aluminum, steel, stainless steel, copper, brass

- • Lead times from 5 business days

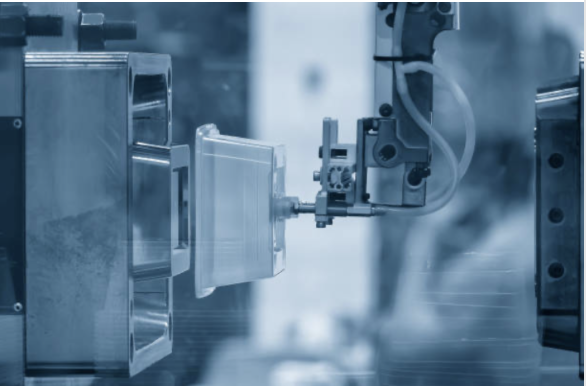

Injection molding

Rapid tooling and production molds

- • Over 30 materials available

- • Lead times from 10 business days

Common materials for robotics

We provide access to strong, lightweight materials and surface finishes that can weather every application.

Metals

Aluminum 6061 & 7075:

Lightweight, high strength-to-weight ratio

Stainless Steel 304 & 316:

Corrosion resistance, high durability

Titanium Grade 5:

Exceptional strength, lightweight

Brass C360:

Low friction, good for gears/bushings

Copper C101:

High electrical conductivity

Tool Steel:

High hardness, wear resistance

Plastics

Nylon (PA12, PA6):

Tough, impact resistant, low friction

Delrin (POM):

High stiffness, low friction, dimensional stability

ABS:

Impact resistance, good machinability

Polycarbonate (PC):

High impact strength, transparency

PEEK:

High performance, heat resistance

TPU/TPE:

Flexible, rubber-like properties

Gallery of robotics parts

Helping robotics companies innovate

Rapid Prototyping

Iterate designs quickly with our fast turnaround times. Test form, fit, and function with production-grade materials before committing to expensive tooling.

Scalable Production

Seamlessly transition from prototyping to low-volume production and mass manufacturing. Our network scales with your needs as your product grows.

Supply Chain Resilience

Mitigate risks with our distributed network of manufacturers. We ensure continuity of supply even during global disruptions.