Compression Molding

All uploads are secure and confidential

Why choose Metal Market?

- Parts as fast as 10 days

- Tight tolerances as low as +/- 0.02"

- Lower tooling costs than injection molding

- Ideal for low to medium volumes

- 9 certified materials available

Why choose compression molding?

High-quality molded rubber and composite parts with lower tooling costs than injection molding. Ideal for producing durable parts with excellent material properties.

Lower Tooling Costs

Significantly reduced tooling investment compared to injection molding, making it cost-effective for low to medium volumes.

Large & Complex Parts

Ideal for manufacturing large, intricate parts that would be difficult or expensive to produce with other methods.

Material Versatility

Work with a wide range of rubber and composite materials including silicone, EPDM, and polyurethane.

Consistent Quality

Produce parts with excellent dimensional stability and consistent mechanical properties across batches.

Our compression molding capabilities

From prototypes to production runs, our compression molding services deliver high-quality rubber and composite parts with precision and consistency.

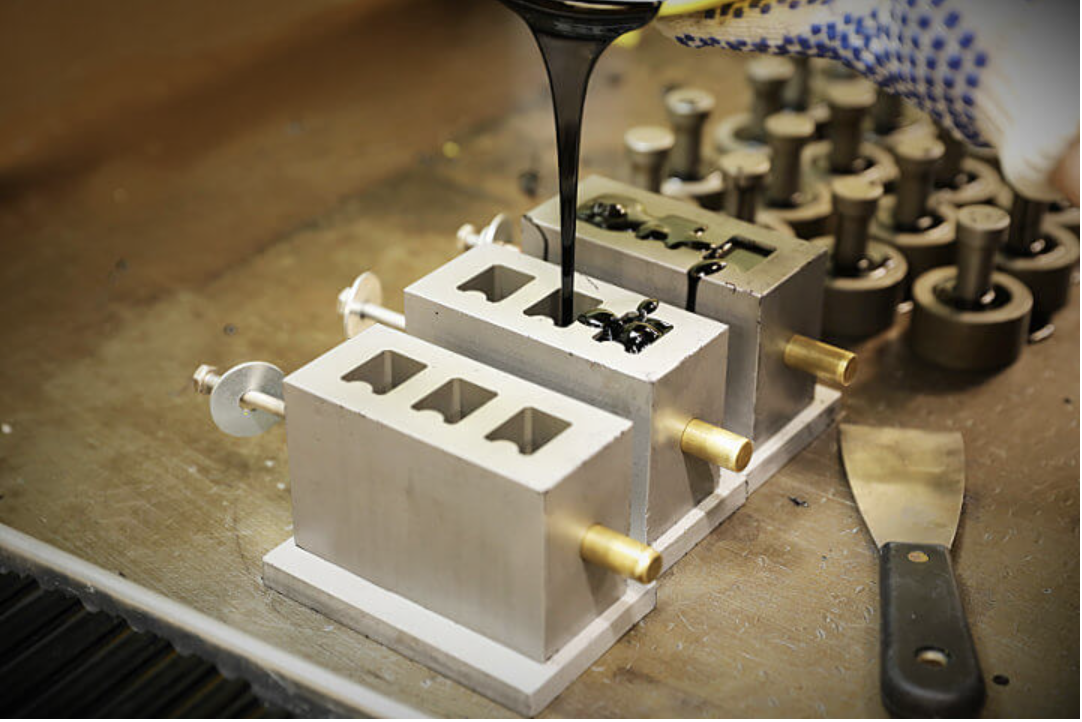

Rubber Compression Molding

Produce durable rubber parts with excellent elasticity, chemical resistance, and longevity. Ideal for seals, gaskets, and industrial components.

- Silicone, EPDM, NBR, and more

- Custom hardness and durometer

- Temperature resistant materials

Composite Compression Molding

Create strong, lightweight composite parts for demanding applications. Perfect for automotive, aerospace, and industrial uses.

- High strength-to-weight ratio

- Complex geometries possible

- Excellent surface finish

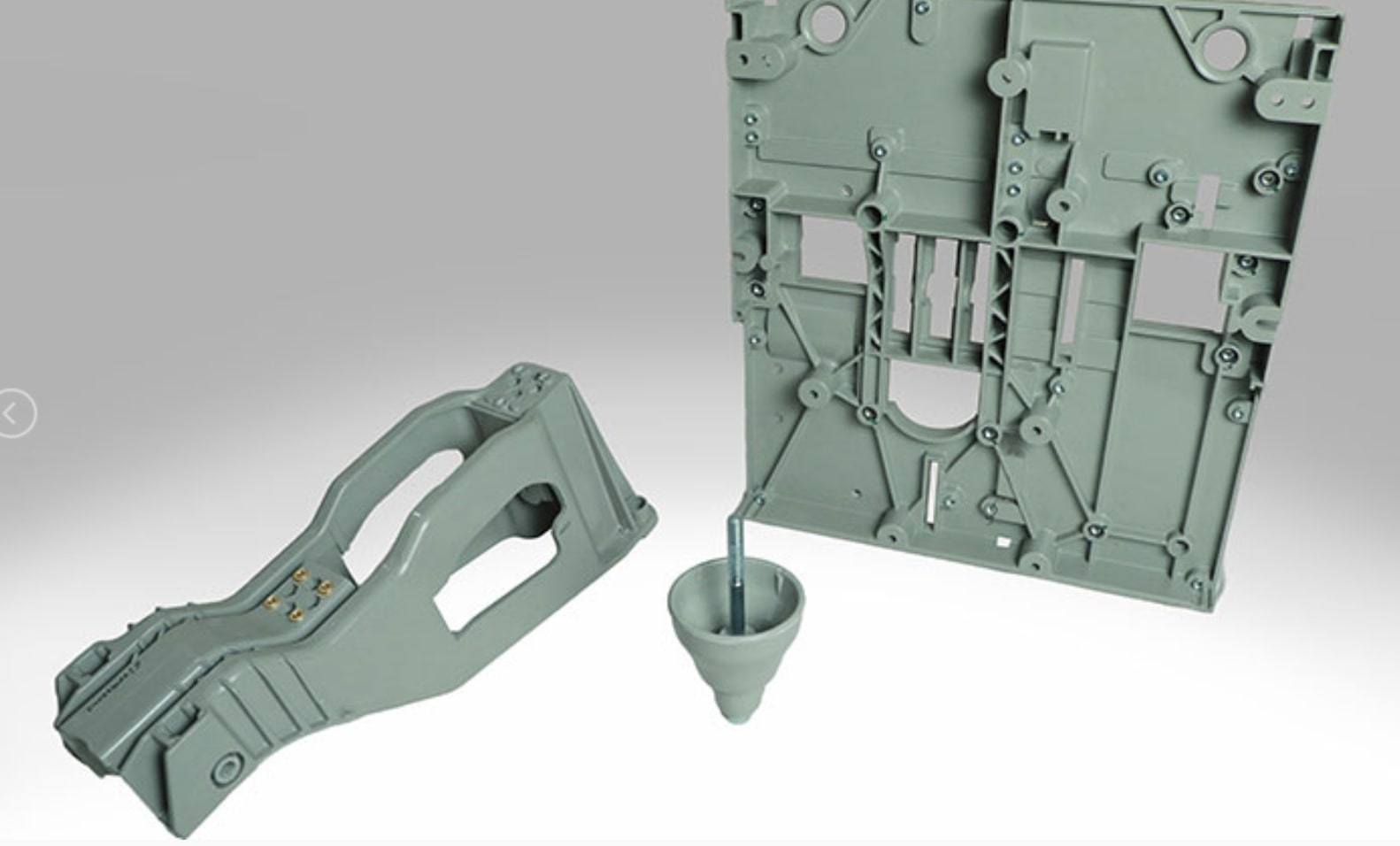

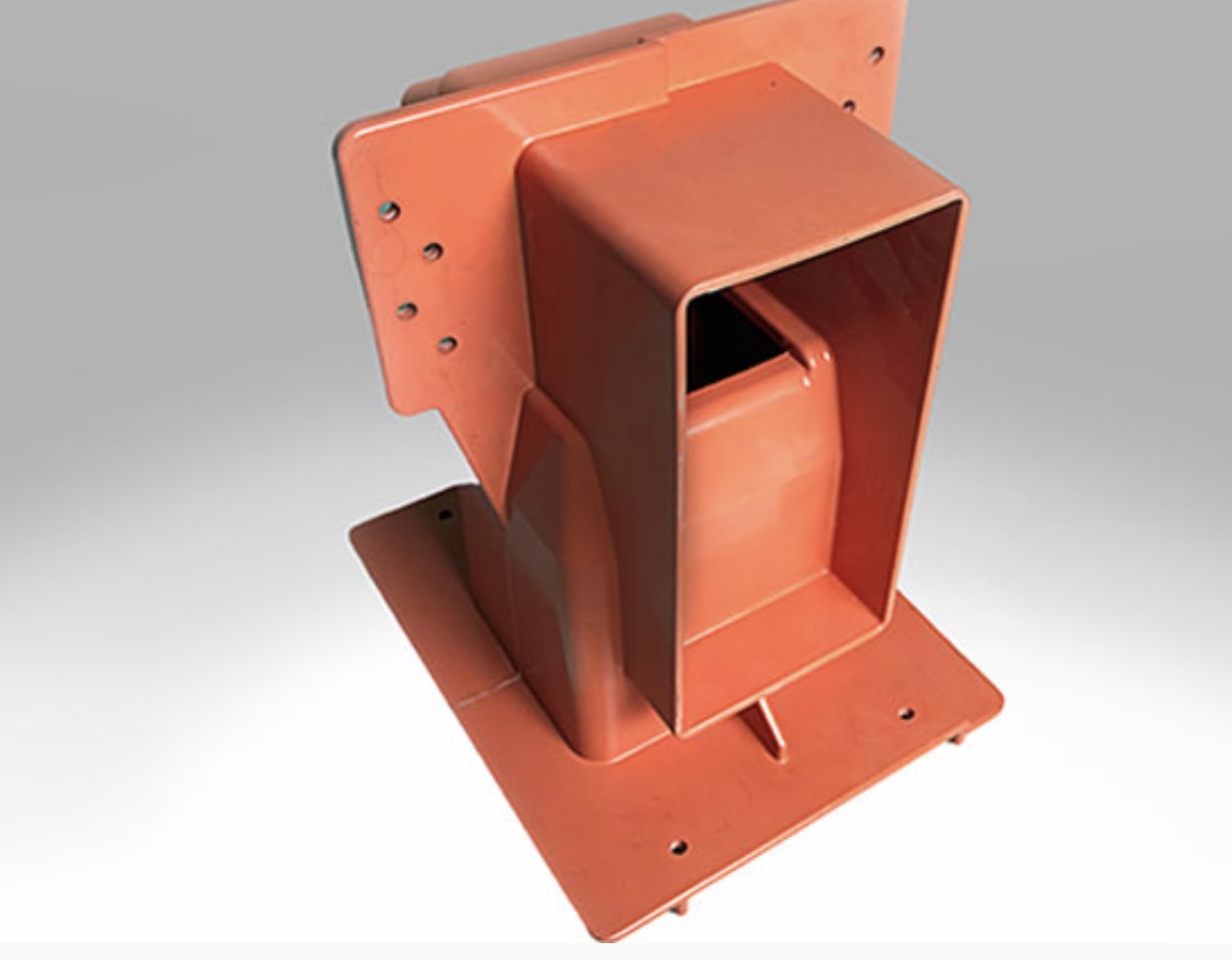

Gallery of compression molded parts

Here's a selection of compression molded rubber and composite parts we've produced for our customers.

Compression molding materials

We offer 9 certified materials for compression molding, each with unique properties suited for different applications.

Silicone

Excellent temperature resistance (-60°C to 230°C), biocompatible, and highly flexible. Ideal for medical, food, and high-temperature applications.

- Temperature resistant

- FDA compliant options

- Excellent flexibility

EPDM Rubber

Outstanding weather, ozone, and UV resistance. Perfect for outdoor applications, automotive seals, and roofing components.

- Weather resistant

- UV stable

- Good chemical resistance

NBR (Buna-N)

Excellent oil and fuel resistance. Commonly used for automotive seals, gaskets, and industrial applications requiring oil contact.

- Oil resistant

- Fuel resistant

- Good abrasion resistance

SBR (Styrene-Butadiene Rubber)

Natural Rubber (NR)

Neoprene (CR)

FKM (Viton)

HNBR

Polyurethane (PU)

We can source other materials on request. Contact us for specific material requirements.

Precision molded tolerances

Part lengths of up to 1000mm × 600mm available. Tolerances listed are minimums for ideal cases.

| Dimension Type | With Drawing | Without Drawing |

|---|---|---|

| Linear Dimension | +/- 0.01 mm (+/- 0.004 inch) | SPI Commercial |

| Hole Diameters | +/- 0.005 mm (+/- 0.002 inch) | SPI Commercial |

Compression molding finishing options

All finishes meet SPI standards for quality and consistency.

Surface Finishes

SPI polished finishes and MT (MoldTech) textured finishes for various aesthetic and functional requirements.

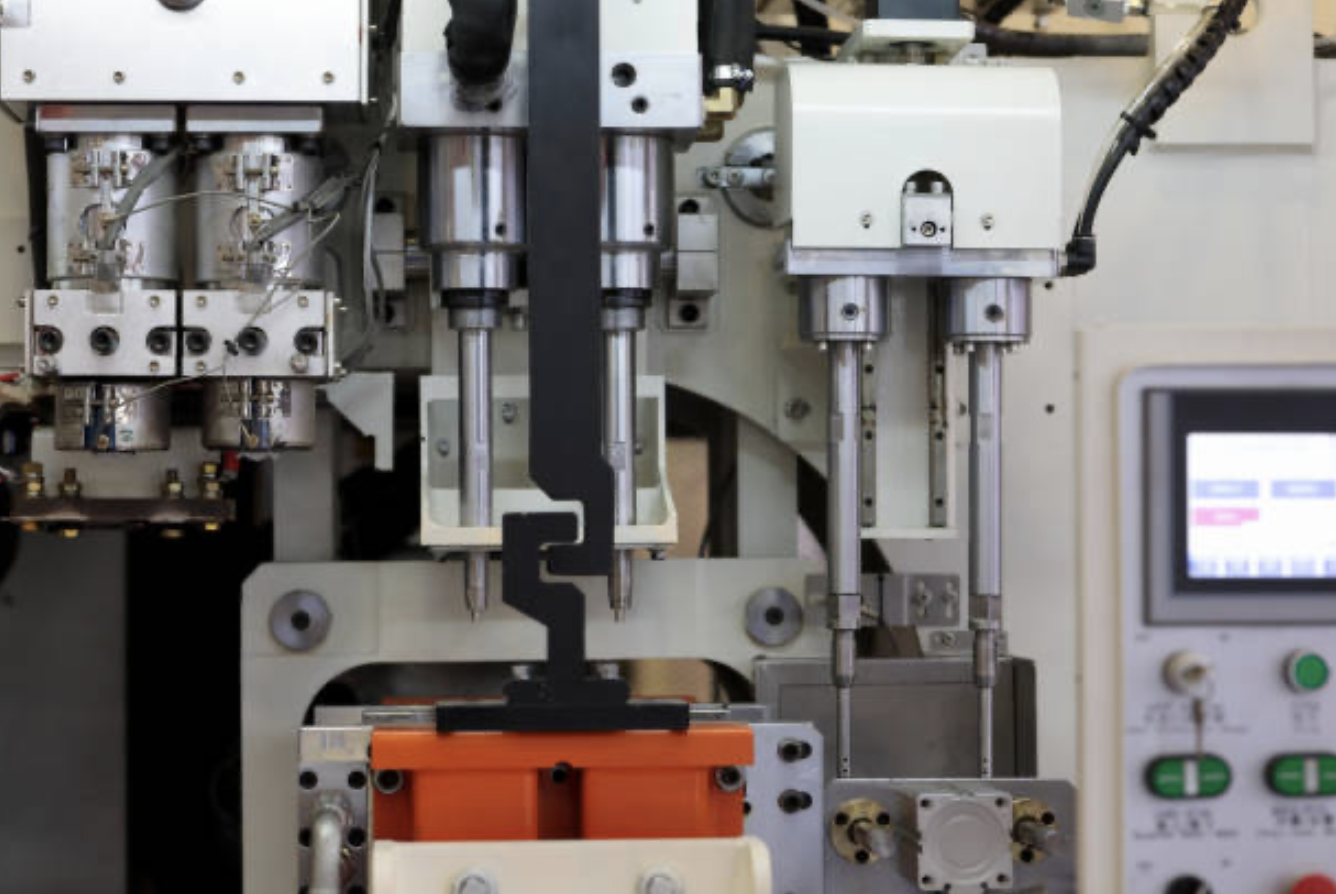

Pad Printing

Applying an ink-based, 2D design to a 3D surface for branding, part identification, or decorative purposes.

Color Matching

Standard colors plus matching to Pantone or RAL number for brand consistency and specific color requirements.

Our ordering process

Upload CAD file

Securely upload your part design to our online quote builder

Confirm specs

Configure your part specifications and select a lead time

Receive quote

Get an instant quote for your parts

Manufacturing

We select the best manufacturer and production begins

Quality control

We ensure parts are manufactured to our standards

Delivery

Your parts are delivered to your door

Specialist industries

Compression molding is widely used across industries requiring durable rubber and composite components.

Automotive

Seals, gaskets, bushings, and vibration dampeners for vehicles and automotive systems.

Medical

Biocompatible silicone components for medical devices, seals, and healthcare equipment.

Industrial Machinery

Heavy-duty rubber components, seals, and protective parts for industrial equipment.

Aerospace

High-performance seals and components meeting strict aerospace standards.

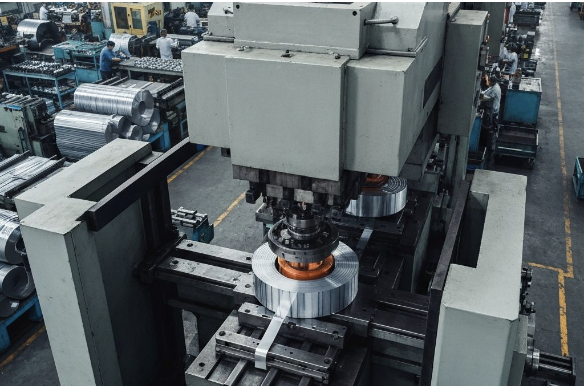

Our other manufacturing capabilities

CNC machining

Milling (3-, 4- & full 5-axis), turning and post-processing

- 50+ metals and plastics & 10 surface finishes

- Tolerances down to ±0.0008" (0.020 mm)

- Lead times from 5 business days

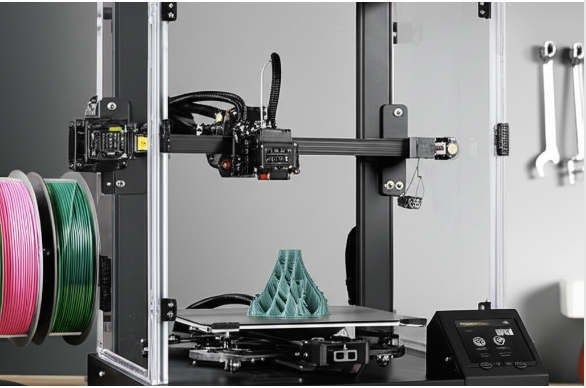

3D printing

FDM, SLS, MJF, SLA

- Dimensional accuracy from 0.2%

- 25+ plastics & 35+ colors

- Lead times from 1 business day

Injection molding

Prototypes and production tooling

- Wide range of part complexities and sizes

- 1 to 1M+ parts production capacity

- Lead times from 10 business days

Sheet metal fabrication

Laser cutting, bending, post-processing

- 6 metals & 9 surface finishes

- Tolerances down to ±0.004" (0.010 mm)

- Lead times from 5 business days

Die casting

High & low pressure casting

- Certified aluminum, zinc & magnesium alloys

- Tolerances as low as +/- 0.003"

- Samples as fast as 10-15 days

Urethane casting

Production quality at low volumes

- ABS-like, Nylon-like, elastomer materials

- Parts as fast as 10 days

- 10-200 units per project

Metal stamping

Progressive die, deep draw, fourslide

- Steel, stainless steel, copper & brass

- Tolerances as low as +/- 0.003"

- Production volumes up to 1M+ parts