Die Casting

All uploads are secure and confidential

Why choose Metal Market?

- 4,100+ materials, process, and finishing options

- ISO 9001:2015 Certified

- Samples as fast as 10-15 days

- Technical support on design and manufacturing

- Robust quality control and testing procedures

Why Choose Die Casting?

High-precision metal parts with integrated post-processing and full-BOM support. T1 samples as fast as 10 days.

Tight Tolerances

As low as +/- 0.003"

Full-BOM Services

Including welding, installation & assembly

Complex Parts

Ideal for bulky, complex, or high-volume parts

No MOQ

No minimum order quantity required

Post-Casting CNC

CNC machining for final features

Multiple Finishes

Chem film, anodizing, plating, powder coat

Quality Reports

Inspection reports with every order

Certified Alloys

Aluminum, zinc, and magnesium alloys

Material Certs

Material certifications & CoCs available

Die Casting at Metal Market

We offer precision components, sustainable practices, and scalable solutions for diverse industries. Your trusted partner for innovative product development and cost-efficient manufacturing.

Part Size

Up to 2500 x 3500 mm, with single-block weights of up to 20 tons

Purity Control

Auto degassing and melting towers for molten metal purity

Porosity Management

Vacuum casting and density index control to manage porosity

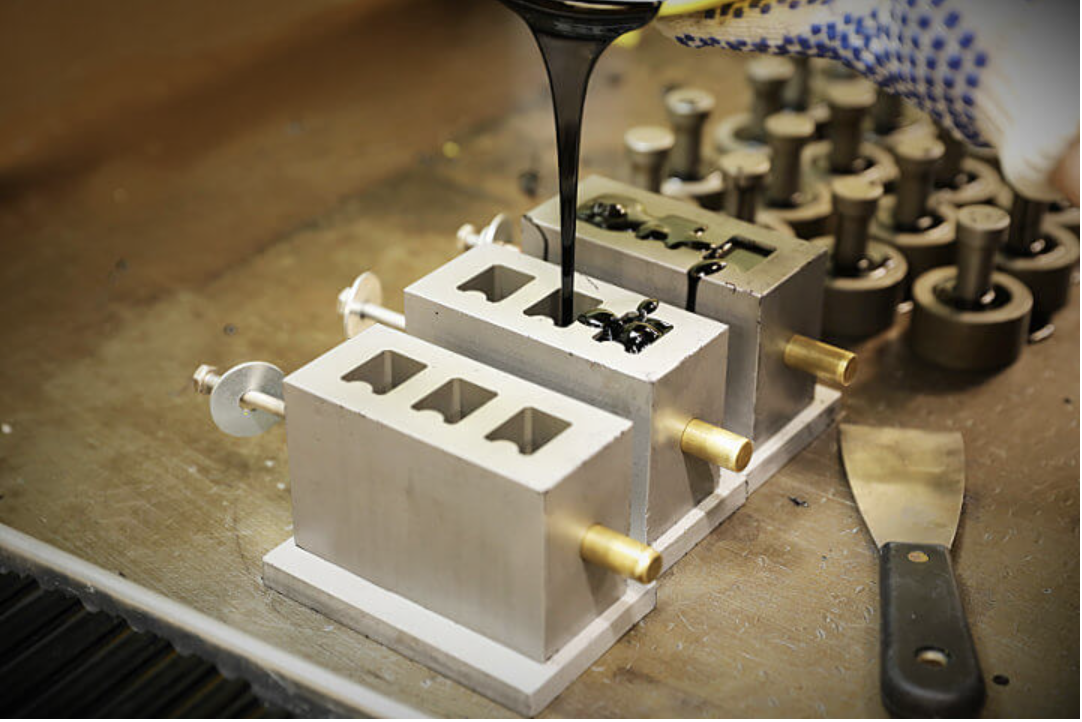

High vs Low Pressure Die Casting

High Pressure Die Casting

A precision manufacturing process that involves injecting molten metal into a steel die or mold at extremely high pressures, typically ranging from 1,000 to 20,000 psi.

- Faster injection speed and cooling rate

- Wall thickness 0.08 to 0.16 inches

- Higher dimensional accuracy

Low Pressure Die Casting

Molten metal is gently poured and propelled into a mold with low-pressure gas at 7-30 PSI. Better suited for complex geometries and allows undercuts.

- Injection pressure 5-30 PSI

- Wall thickness over 0.18 inches

- Supports undercuts and complex shapes

Die Casting Capabilities

Lead Time

Sample parts as fast as 10-15 days

Tooling

Made from H13 hardened steel

Tolerances

+/- 0.1 mm per 25 mm for raw casting & +/- 0.05 mm for post-CNC machined features

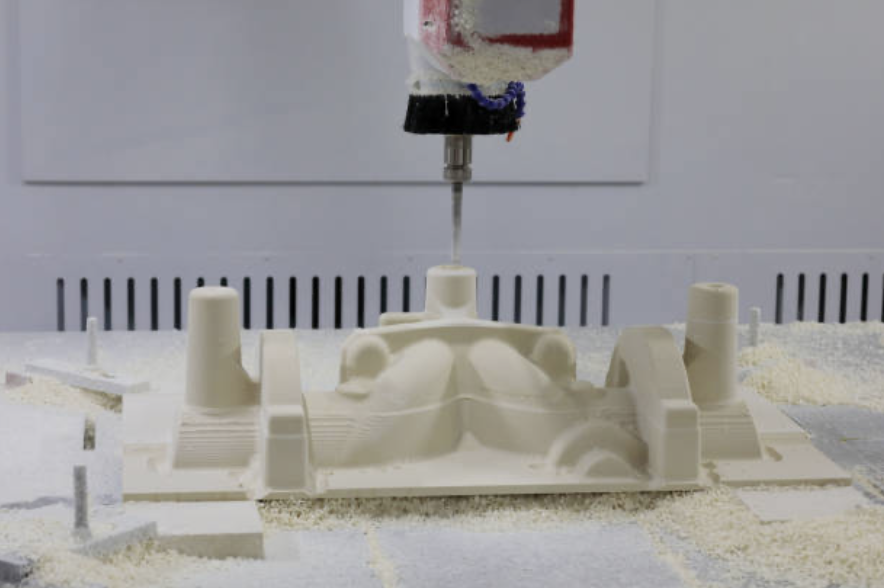

Rapid Prototyping

3D-printed wax patterns for quick-cast tooling

3D Scanning

For rapid design validation or reverse engineering

Advanced Software

Mold flow analysis and CAD/CAM systems

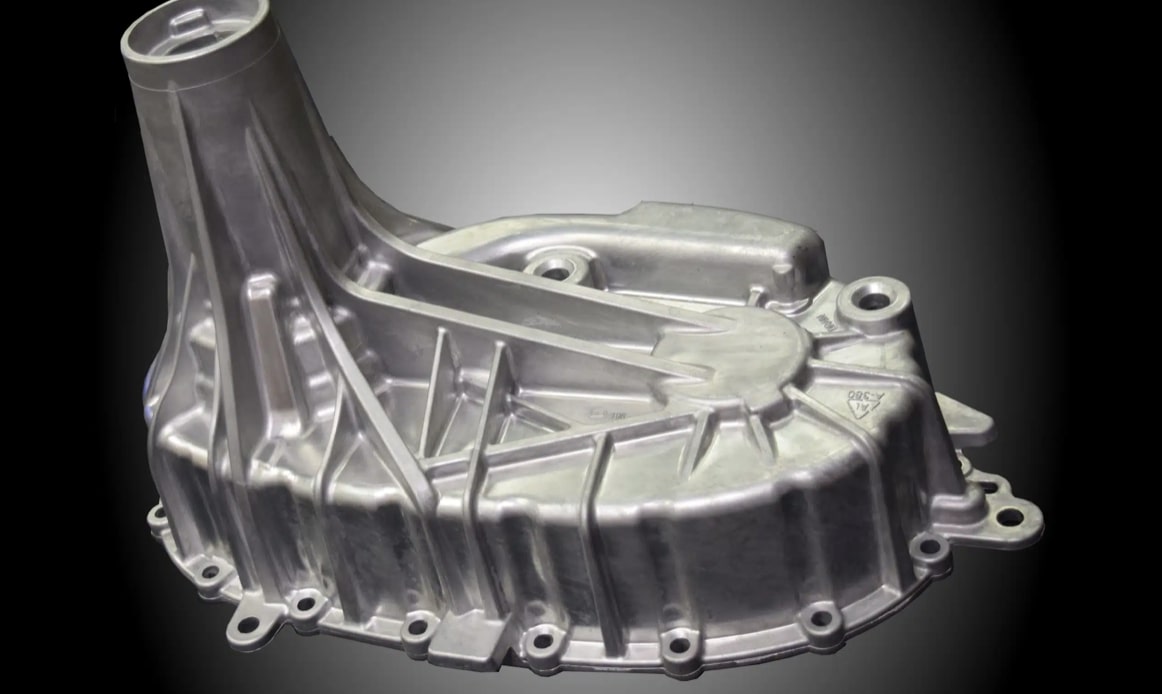

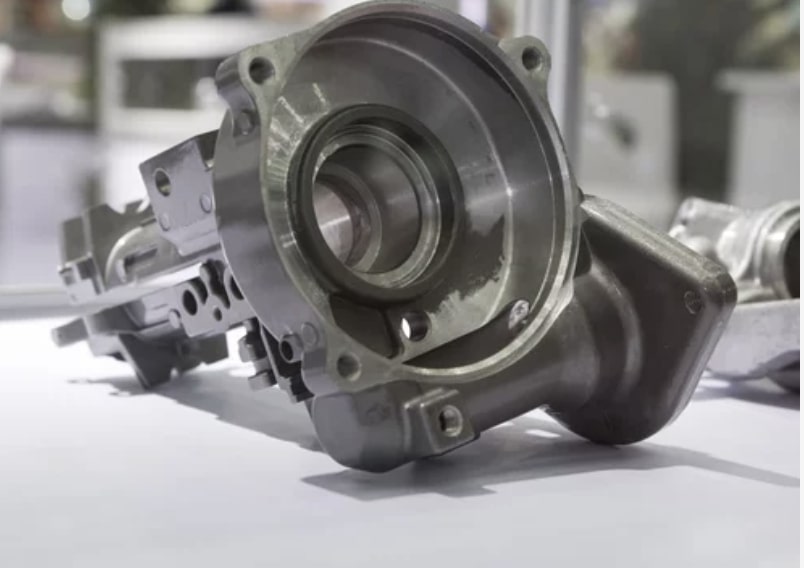

Gallery of die cast parts

Here's a selection of die cast prototypes and production parts we've produced for our customers.

Die Casting Materials

We offer certified aluminum, zinc, and magnesium alloys for die casting applications.

Aluminum Alloys

ADC12 Aluminum

Most common die casting alloy with excellent fluidity

A380 Aluminum

Excellent combination of casting properties

ADC10 Aluminum

Good corrosion resistance and thermal conductivity

A383 Aluminum

Better die filling for complex parts

A390 Aluminum

High silicon content for wear resistance

Zinc Alloys

Zamak 3 Zinc Alloy

Most widely used zinc alloy, excellent balance of properties

Zamak 5 Zinc Alloy

Higher strength and hardness than Zamak 3

Magnesium Alloys

AZ91D Magnesium

Lightest structural metal, excellent strength-to-weight ratio

Surface Finishes

Multiple finishing options available for die cast parts.

Alodine (Chromate Conversion)

Corrosion protection for aluminum

Anodizing

Enhanced corrosion resistance and aesthetics

Electroless Nickel Plating

Uniform coating regardless of geometry

Nickel Plating

Improved hardness and wear resistance

Powder Coating

Durable, decorative finish in various colors

Tumbling

Deburring and surface smoothing

Additional finishing options include chromic acid anodizing, cadmium plating, copper plating, titanium anodizing (blue anodizing), gold plating, silver plating, and more.

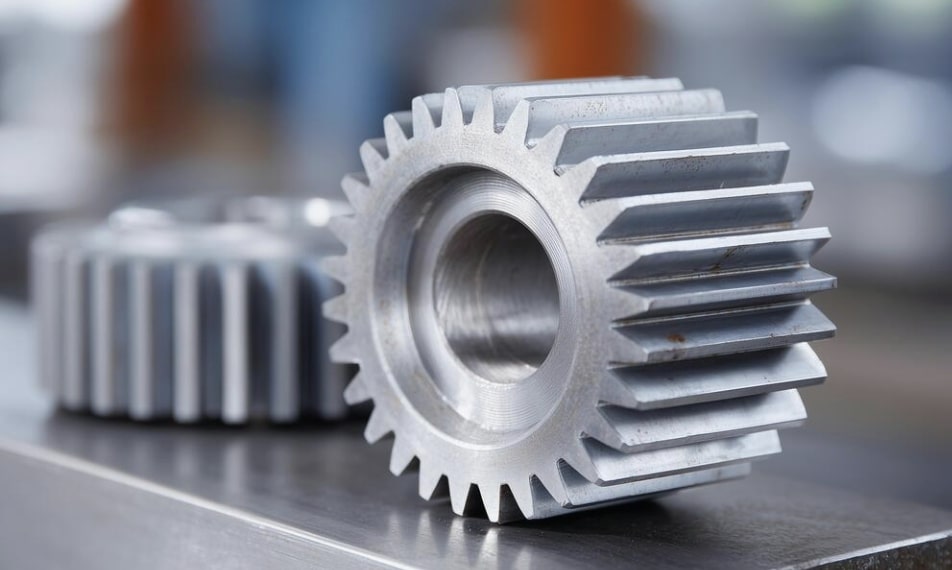

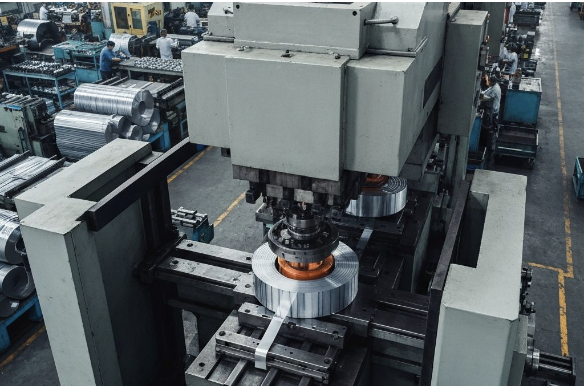

Post-Casting CNC Machining

We offer the equipment and processes to handle all your CNC machining needs after die casting. Sometimes a part requires clean up or detailed features to be machined post-casting.

5-Axis Machining Centers

For complex geometries requiring multi-angle machining in a single setup.

Wire EDM & Graphite Machining

For fine details and intricate features that require precision cutting.

Reliable Die Casting Quality

Our commitment to maintaining rigorous appearance standards and rejection criteria ensures the final product consistently meets customer expectations.

High vs Low Pressure Die Casting

| Feature | Low Pressure | High Pressure |

|---|---|---|

| Injection Pressure | 5-30 PSI | 1,000-20,000 PSI |

| Injection Speed | Slow | Fast |

| Cooling Rate | Standard | Faster |

| Wall Thickness | >0.18 inches | 0.08-0.16 inches |

| Undercuts | Yes | No |

| Complex Geometries | Better Suited | Good |

| Dimensional Accuracy | Good | Higher |

Prototype Die Casting

T1 Samples As Quick As 10 Days

High quality parts done fast, per your design, and to print tolerances.

Easy to Use Manufacturing Platform

Expert support from design to molding and engineering changes.

Guided Expertise

We have the skillset and experience for DFM and prototyping process selection.

Production Die Casting

Cost Down Analysis

We partner with you to do cost down analysis to meet your requirements.

Dedicated Global Team

Manufacturing engineers, technical program management, SQE, tooling engineers assigned to each program.

Complete Quality Systems

APQP full program planning, PPAP, scientific molding, tooling inspection, and automation.

Frequently asked questions

Our other manufacturing capabilities

CNC machining

Milling (3-, 4- & full 5-axis), turning and post-processing

- 50+ metals and plastics & 10 surface finishes

- Tolerances down to ±0.0008" (0.020 mm)

- Lead times from 5 business days

3D printing

FDM, SLS, MJF, SLA

- Dimensional accuracy from 0.2%

- 25+ plastics & 35+ colors

- Lead times from 1 business day

Injection molding

Prototypes and production tooling

- Wide range of part complexities and sizes

- 1 to 1M+ parts production capacity

- Lead times from 10 business days

Sheet metal fabrication

Laser cutting, bending, post-processing

- 6 metals & 9 surface finishes

- Tolerances down to ±0.004" (0.010 mm)

- Lead times from 5 business days

Compression molding

Rubber and composite parts

- 9 certified materials including silicone & EPDM

- Tolerances as low as +/- 0.02"

- Lead times from 10 business days

Urethane casting

Production quality at low volumes

- ABS-like, Nylon-like, elastomer materials

- Parts as fast as 10 days

- 10-200 units per project

Metal stamping

Progressive die, deep draw, fourslide

- Steel, stainless steel, copper & brass

- Tolerances as low as +/- 0.003"

- Production volumes up to 1M+ parts