Metal Stamping Services

All uploads are secure and confidential

Why choose Metal Market?

- Production volumes up to 1M+ parts

- Tolerances down to ±0.003"

- Multiple stamping techniques available

- ISO 9001:2015 certified partners

- Lead times from 10 business days

Our metal stamping service capabilities

Metal stamping is a manufacturing process in which coils or flat sheets of material are formed into specific shapes. Stamping encompasses multiple forming techniques such as blanking, punching, embossing, and progressive die stamping. We offer production volumes of over one million parts and maintain tight tolerances, all with competitive lead times.

Progressive Die Stamping

Uses multiple dies and steps to create deeper parts than would typically be achievable through single dies. Best suited for high volume and large automotive parts.

Deep Draw Stamping

Creates stampings with deep cavities, like enclosed rectangles. The extreme deformation compresses the metal into a more crystalline, rigid form.

Types of Metal Stamping

We offer single and multistage, progressive die, deep draw, fourslide, and other stamping methods to ensure the most effective method for manufacturing your products.

Progressive Die Stamping

Uses multiple dies and steps to create deeper parts. Best suited for high volume and large automotive parts.

Deep Draw Stamping

Creates stampings with deep cavities. The extreme deformation compresses metal into a rigid crystalline form.

Fourslide Stamping

Shapes parts from four axes for small intricate parts like electronics components and phone battery connectors.

Hydroforming

Uses high-pressure oil bladder to press metal into shape. Quick and accurate for multiple parts simultaneously.

Blanking & Fineblanking

Cuts pieces from sheet as initial step. Fineblanking makes precise cuts with smooth edges and flat surfaces.

Embossing & Coining

Creates three-dimensional designs raised above surface or through depressions. Coining hardens and removes burrs.

Gallery of metal stamped parts

See examples of our precision metal stamped components across various industries.

Metal Stamping Materials

We offer a wide range of materials for both standard and custom metal stampings.

Steel

CRS steel like 1008, 1010, or 1018. General-purpose material perfect for cold forming.

Stainless Steel

301, 304, and 316/316L. Excellent tensile strength and corrosion resistance at higher temperatures.

Copper

Including C110, which is a powerful conductor and easily formable.

Brass

Brass 230 (85/15) and 260 (70/30) are highly formable and corrosion-resistant.

We can stamp other sheet metal materials on request. Our stamping materials can be post-processed with bead blasting, powder coating, chem film, anodizing, and plating in gold, silver, or electroless nickel.

Production Volumes

We offer a wide variety of production volumes for sheet metal stamping.

Low Volume Production

Up to 100,000 units

Ideal for bridging development between prototypes and mass manufacturing. See how well a product will do on the market with low per-unit costs.

Medium Volume Production

100,000 - 1 million units

Offers flexibility of low-volume orders while enabling lower price per part and lower up-front costs for tooling.

High Volume Production

Over 1 million parts

Incredibly cost-effective for high volumes, driving down unit costs stemming from the price of creating custom tooling.

Short Run Stamping

Limited tool revisions

Overall costs will be less since you won't need to change processes or equipment. Best for parts requiring less flexibility.

Advantages of Metal Stamping

- Complex forms, such as contours

- High volumes (from thousands to millions of parts per year)

- Fineblanking allows for forming of thick metal sheets

- Low cost-per-piece prices

- Consistent quality and precision

Considerations

- Longer lead times on first parts (time needed to create dies)

- Tooling, check fixtures, and non-renewable engineering drive upfront costs

- Die design may need multiple iterations before production commences

Our ordering process

Upload CAD file

Securely upload your part design to our online quote builder

Confirm specs

Configure your part specifications and select a lead time

Receive quote

Get an instant quote for your parts

Manufacturing

We select the best manufacturer and production begins

Quality control

We ensure parts are manufactured to our standards

Delivery

Your parts are delivered to your door

Metal Stamping by Industry

We offer metal stamping services that cater to a variety of different industries and applications.

Automotive

Metal stamping creates hundreds of different automotive parts, from chassis to door panels to seat belt buckles.

Aerospace

Critical process in the aerospace sector for a wide range of parts and components.

Medical

Precision metal stamping creates parts and components with quality and tolerances needed in the medical space.

Consumer Electronics

Small electrical components used in phones, computers, and other electronic devices.

Frequently asked questions

Our other manufacturing capabilities

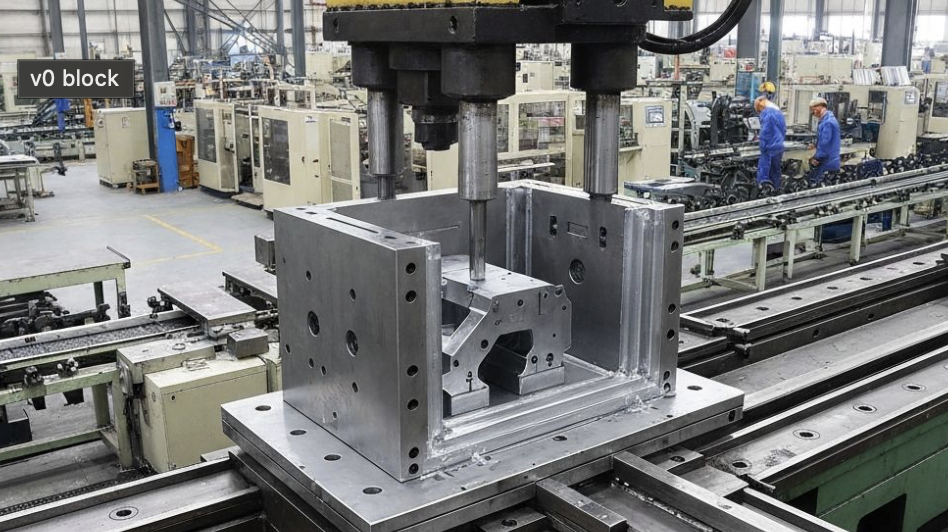

CNC machining

Milling (3-, 4- & full 5-axis), turning and post-processing

- 50+ metals and plastics & 10 surface finishes

- Tolerances down to ±0.0008" (0.020 mm)

- Lead times from 5 business days

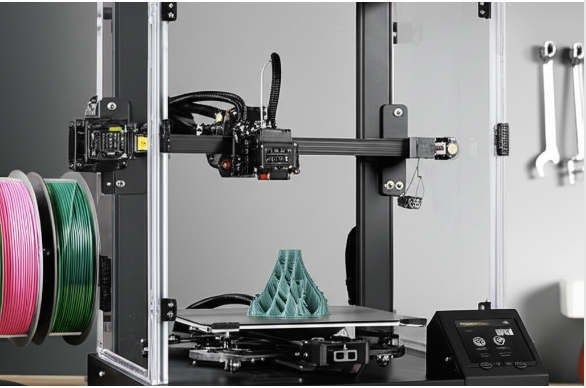

3D printing

FDM, SLS, MJF, SLA

- Dimensional accuracy from 0.2%

- 25+ plastics & 35+ colors

- Lead times from 1 business day

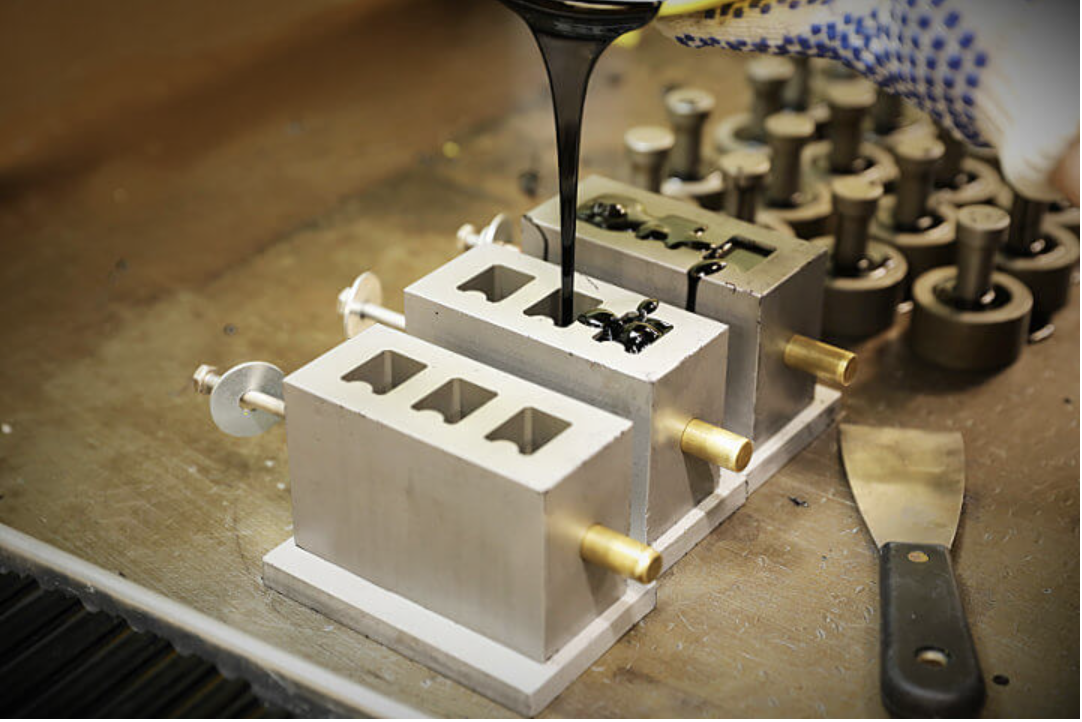

Injection molding

Prototypes and production tooling

- Wide range of part complexities and sizes

- 1 to 1M+ parts production capacity

- Lead times from 10 business days

Sheet metal fabrication

Laser cutting, bending, post-processing

- 6 metals & 9 surface finishes

- Tolerances down to ±0.004" (0.010 mm)

- Lead times from 5 business days

Compression molding

Rubber and composite parts

- 9 certified materials including silicone & EPDM

- Tolerances as low as +/- 0.02"

- Lead times from 10 business days

Die casting

High & low pressure casting

- Certified aluminum, zinc & magnesium alloys

- Tolerances as low as +/- 0.003"

- Samples as fast as 10-15 days

Urethane casting

Production quality at low volumes

- ABS-like, Nylon-like, elastomer materials

- Parts as fast as 10 days

- 10-200 units per project