MARTISTEL: TRANSFORMING WAREHOUSE AUTOMATION THROUGH PRECISION MANUFACTURING

How MetalMarket Technologies Helped Martistel Go from Prototype to Mass Production

Results Achieved

Compared to domestic suppliers, with very competitive production costs.

20% faster than industry standard, with 30-day batch production.

0.05–0.2 mm tolerances consistently across 58,000 kg volumes.

Martistel successfully raised Series A funding, entered USA, UAE, and Russian markets with firm purchase orders, and scaled from 300 kg prototype samples to 58,000+ kg batches.

The Breakdown

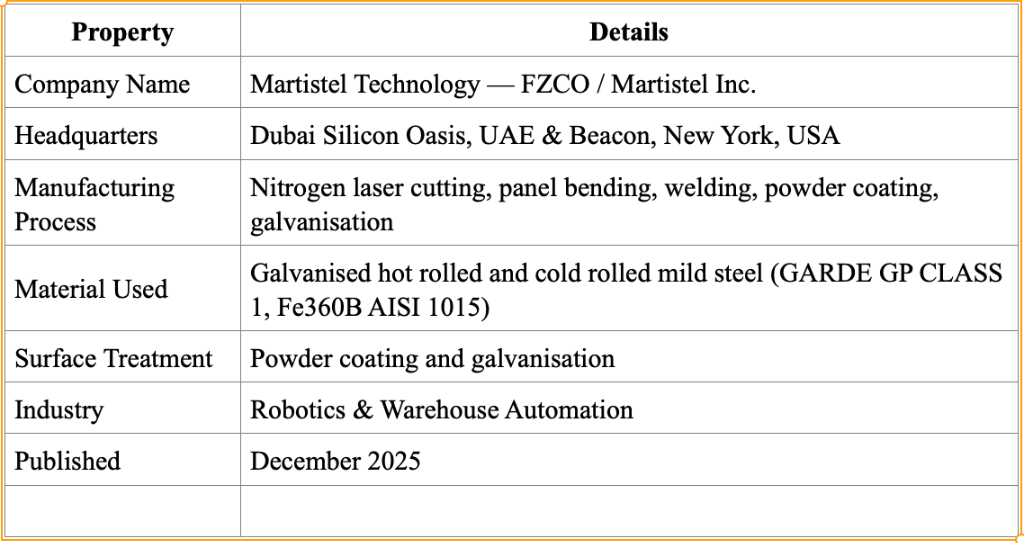

Company: Martistel Technology — FZCO / Martistel Inc.

Location: Dubai Silicon Oasis (HQ) & Beacon, NY

Industry: Robotics & Automation

Why MetalMarket Technologies?

One-stop solution for multi-category SKU production with tight tolerances and cost-effectiveness

About The Company

Martistel Technology was founded by Oleg Sultanov. The company develops high-density robotic automation systems for warehouses and fulfillment centers. Their technology allows warehouses to store more inventory in the same space while processing orders faster. Basically, they use robotics to make warehouse operations more efficient and reduce manual work.

The Challenge: Manufacturing Was A Headache

When Martistel wanted to launch their warehouse automation system commercially, they faced one major problem - manufacturing was complicated and time was running out.

They couldn't find a single manufacturer who could handle everything. Martistel needed sheet metal parts, plastic parts, and rubber parts - and normally these come from three to four different suppliers. This created multiple issues:

- Quality was inconsistent - each manufacturer had different standards

- Costs were higher - managing multiple vendors meant no price leverage

- Large manufacturers refused - 300 kg samples were too small for them

- Tolerances were very tight - they needed 0.05 to 0.2 mm precision for 6-meter structural channels

The GITEX 2024 conference was coming - they had to showcase their product there. So they needed a manufacturing partner who could deliver quality prototypes not in months, but in weeks.

The Solution: One-Stop Manufacturing Partner

MetalMarket Technologies India provided exactly what Martistel needed - everything from one place, with proper quality. The partnership was built on three main capabilities:

All Manufacturing in One Location

MetalMarket handled:

- Sheet metal structural components

- Plastic and rubber parts through partner network

- Complex assemblies with precise fitment

Fast Sampling and Delivery

- Phase 1: 15 days to first prototypes

- Phase 2: 3 rounds of iterative sampling

- Phase 3: 6 tonnes batch in 30 days for GITEX

- Phase 4: 58,000 kg mass production batches

Engineering Support and Collaboration

MetalMarket partner manufacturer’s engineers worked directly with Martistel's design team to identify critical tolerances, optimize material selection, and resolve design challenges through 24/7 support.

How Development Accelerated

"Very good experience. It saved both time and money - we were able to launch our product on schedule."

— Oleg Sultanov, CEO of Martistel

For a startup, this partnership meant design iterations in weeks (not months), known production costs upfront, and lower risk market entry. Martistel manufactured structural chassis, tote frame assemblies (up to 5.6 meters), multi-tier support structures, and precision interface components—all quality verified with international certifications (ISO 9001, AS9100, etc.).

Design Optimization Through Teamwork

The biggest value came from engineering collaboration. MetalMarket's engineers identified areas where Martistel could improve their design without losing quality. Through multiple iterations, they found ways to:

- Optimize material selection: Cold-rolled versus hot-rolled steel based on actual needs

- Refine manufacturing methods: Better laser cutting parameters to reduce secondary work

- Reduce costs: Value engineering brought unit costs down 30%

Why This Partnership Worked

Understood startup economics & business pressures

Handled complex supply chains (no multiple vendors)

Collaborated actively on problems

Maintained quality at any scale (300kg to 58,000kg)

Provided complete transparency & quality verification

Available 24/7 for immediate support

Result? Martistel entered the market 6 months faster than it would have alone. Today, Martistel's warehouse automation systems are transforming logistics operations around the world.

Ready to start your success story?

Get an instant quote and bring your product to life.

Get an instant quote